News

NEWS CENTER

- Company News

- Industry Express

-

Intelligent Welding Technology for Industrial Aluminum Profile of EMUs

The vehicle body made of industrial aluminum profile materials has the advantages of light weight, corrosion resistance, good appearance flatness and recyclable materials, so it is favored by urban transportation companies and railway transportation departments around the world. Industrial alumin...

View More -

How to Optimize the Design of Aluminum Extrusion to Achieve Cost Reduction and High Efficiency

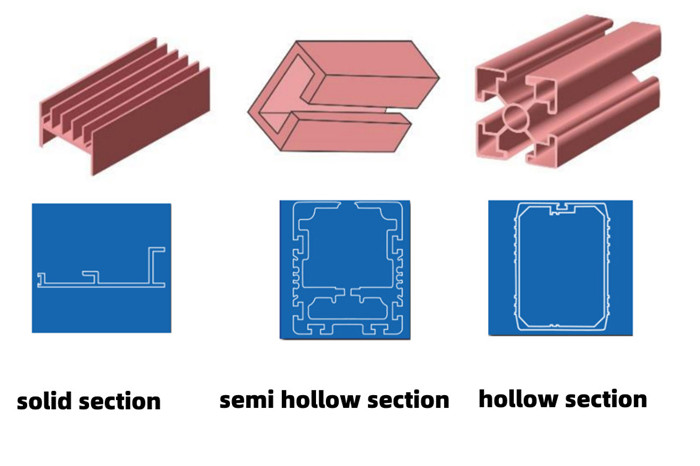

The section of aluminum extrusion is divided into three categories: Solid section: low product cost, low mold cost Semi hollow section: the mold is easy to wear and tear and break, with high product cost and mold cost Hollow section: high product cost and mold cost, the highest mold cost for poro...

View More -

Goldman Raises Aluminum Forecasts on Higher Chinese and European Demand

▪ The bank says the metal will average $3,125 a ton this year ▪ Higher demand could ‘trigger scarcity concerns,’ banks says Goldman Sachs Group Inc. raised its price forecasts for aluminum, saying higher demand in Europe and China could lead to supply shortages. The metal will probably aver...

View More

-

03 Feb . 26

Cracking the Five Major Defects in Aluminum Deep-Processing Casting: A Practical Guide to Combined Grain Refinement and Melt Purification Technologies

Aluminum deep-processing casting is a core link in the aluminum alloy industry chain. Product quality at this stage directly determines the performance of downstream components used in aerospace, new energy vehicles, high-end equipment, and other advanced fields. With the revision and implementat...

View More -

Melt Treatment Technology of Aluminum Alloys:Principles, Key Processes, and Industrial Applications

Aluminum alloy melt treatment (Melt Treatment of Aluminium) is a core process in the aluminum processing industry chain, directly determining the internal quality, mechanical properties, and service life of castings and wrought products. As the critical link connecting raw material melting and fi...

View More -

Typical Problems, Formation Mechanisms, and Countermeasures in the Aluminum Alloy Melting Process

Aluminum alloys are widely used in aerospace, automotive manufacturing, rail transit, and architectural decoration due to their low density, high specific strength, corrosion resistance, and excellent processing performance. Melting is the core process in aluminum alloy production, directly deter...

View More