1. Characteristics of aluminum and aluminum alloy special precision extrusion materials

This type of product has special shape, thin wall thickness, light unit weight, and very strict tolerance requirements. Such products are usually called aluminum alloy precision (or ultra-precision) profiles (pipes), and the technology for producing such products is called precision. (or ultra-precision) extrusion.

The main features of aluminum alloy special precision (or ultra-precision) extrusions are:

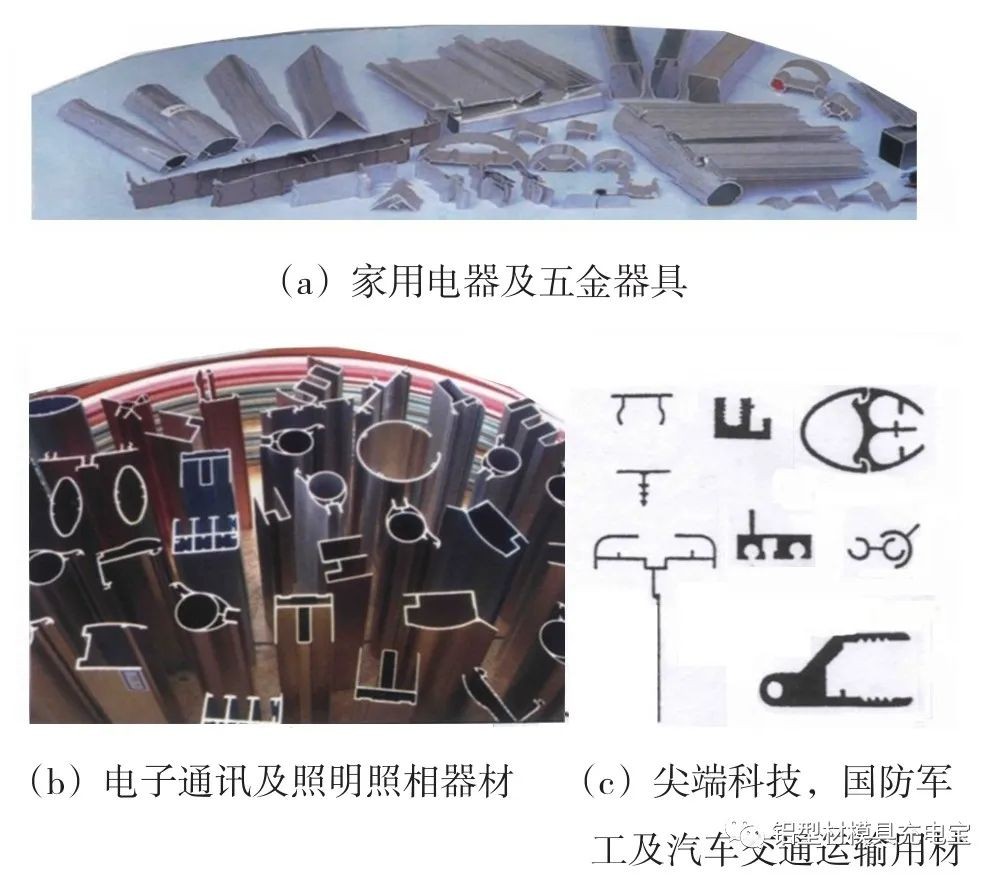

(1)There are many varieties, small batches, and most of them are special-purpose extrusion materials, which are used in almost all walks of life and all aspects of people’s lives, including all extrusion products, such as pipes, bars, profiles and wires, involving various alloy and state. Because of its small cross-section, thin wall thickness, light weight, and small batches, it is generally not easy to organize production.

(2) Complicated shapes and special contours, mostly shaped, flat, wide, winged, toothed, porous profiles or pipes. The surface area per unit volume is large, and the production technology is difficult.

(3) Wide application, special performance and functional requirements. In order to meet the use requirements of the product, many alloy states are selected, covering almost all alloys from 1××× to 8××× series and dozens of treatment states, with high technical content.

(4) Exquisite appearance and thin wall thickness, generally less than 0.5mm, some even reach about 0.1mm, the weight per meter is only a few grams to tens of grams, but the length can reach several meters, or even hundreds of meters.

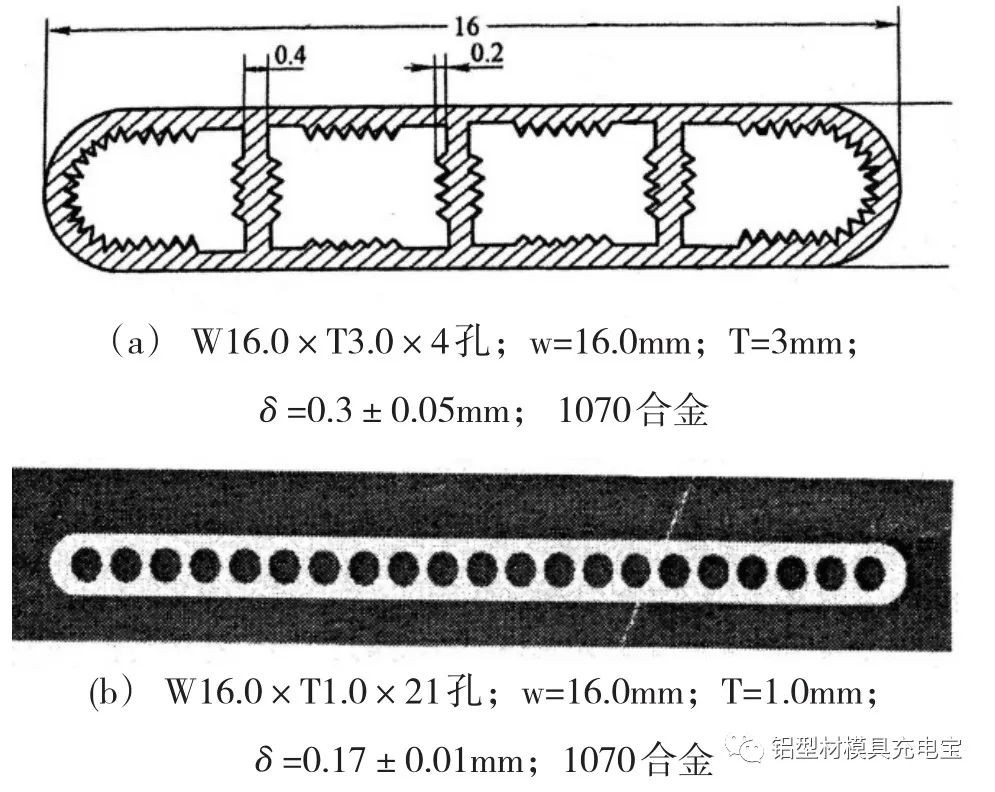

5) The dimensional accuracy and geometric tolerance requirements of the section are very strict. Generally speaking, the tolerances of small aluminum alloy precision profiles are more than twice as strict as the special grade tolerances in JIS, GB, and ASTM standards. The wall thickness tolerance of general precision aluminum alloy profiles is required to be between ±0.04mm and 0.07mm, while the section size tolerance of ultra-precision aluminum alloy profiles may be as high as ±0.01mm. For example, the weight of the precision aluminum profile used for the potentiometer is 30g/m, and the tolerance range of the section size is ±0.07mm. The cross-sectional size tolerance of precision aluminum profiles for looms is ±0.04mm, the angle deviation is less than 0.5°, and the bending degree is 0.83×L. Another example is the high-precision ultra-thin flat tube for automobiles, with a width of 20mm, a height of 1.7mm, a wall thickness of 0.17±0.01mm, and 24 holes, which are typical ultra-precision aluminum alloy profiles.

(6) It has high technical content and is very difficult to produce, and has special requirements for extrusion equipment, tools, billets and production processes. Figure 1 is an example of the section of some small precision aluminum alloy profiles.

2. Classification of aluminum alloy special precision extrusion materials

Precision or ultra-precision aluminum alloy extrusions are widely used in electronic instruments, communication equipment and cutting-edge science, national defense and military industry, precision mechanical instruments, weak current equipment, aerospace, nuclear industry, energy and power, submarines and ships, automobiles and transportation tools , medical equipment, hardware tools, lighting, photography and electronic appliances. Generally speaking, precision or ultra-precision aluminum alloy extrusions can be divided into two categories according to their appearance characteristics: the first category is profiles with small dimensions. This type of profile is also called ultra-small profile or mini-shape. Its overall size is usually only a few millimeters, the minimum wall thickness is less than 0.5mm, and the unit weight is several grams to tens of grams per meter. Due to their small size, tight tolerances are usually required on them. For example, the tolerance of cross-sectional dimensions is less than ±0.05mm. In addition, the requirements for straightness and torsion of extruded products are also very strict.

The other type is profiles that are not very small in cross-sectional size but require very strict dimensional tolerances, or profiles that have a complex cross-sectional shape and thin wall thickness although the cross-sectional size is large. Figure 2 shows the special-shaped tube (industrial pure aluminum) extruded by a Japanese company on a 16.3MN horizontal hydraulic press with a special split die for an automotive air-conditioning condenser. The difficulty of extrusion forming of this type of profile is no less than that of the former type of ultra-small profile. Extruded profiles with large section size and very strict tolerance requirements not only require advanced mold design technology, but also require strict management technology for the entire production process from blank to finished product.

Since the early 1980s, due to the practical application of Conform continuous extrusion technology and the development of industrial technology, the extrusion of small and ultra-small profiles has developed rapidly. However, due to various reasons such as equipment limitations, product quality requirements, and advancements in extrusion technology, the production of small profiles on conventional extrusion equipment still accounts for a large proportion. Figure 2 shows the precision profiles of the extrusion of conventional split dies. The life of the mold (especially the strength and wear resistance of the shunt bridge and the mold core) and the material flow during extrusion become the main factors affecting its production. This is because when extruding the profile, the size of the mold core is small and the shape is complex, and strength and wear resistance are important factors affecting the life of the mold, the mold life directly affects the production cost. On the other hand, many precision profiles have thin walls and complex shapes, and the flow of materials during the extrusion process directly affects the shape and dimensional accuracy of the profiles.

In order to prevent the oxide film and oil on the surface of the billet from flowing into the product and ensure the uniform and reliable quality of the product, the billet heated to the set temperature can be peeled before extrusion (called hot peeling), and then quickly put into the extrusion barrel for extrusion. At the same time, the extruded gasket should be kept clean to prevent oil and dirt from adhering to the gasket during the process of removing excess pressure after one extrusion and installing the gasket in the next extrusion.

According to section dimensional accuracy and shape and position tolerance, special precision aluminum alloy extrusion can be divided into special precision aluminum alloy profiles and small (miniature) ultra-high precision aluminum alloy profiles. In general, its accuracy exceeds the national standard (such as GB, JIS, ASTM, etc.) ultra-high precision is called special precision aluminum alloy profiles, for example, the dimensional tolerance is above ±0.1mm, the wall thickness tolerance of the broken surface is within ±0.05mm ~ ±0.03mm profiles and pipes.

When its accuracy is more than double the national standard ultra-high precision, it is called a small (miniature) ultra-high precision aluminum alloy profile, such as a shape tolerance of ±0.09mm, wall thickness tolerance of ±0.03mm ~ ±0.01mm for a small (miniature) profile or pipe.

3. Development prospects of aluminum and aluminum alloy special precision extrusion materials

In 2017, the production and sales of aluminum processing materials in the world exceeded 6000kt/a, of which the production and sales of aluminum and aluminum alloy extrusion materials exceeded 25000kt/a, accounting for more than 40% of the total production and sales of aluminum. Aluminum extruded medium bars accounted for 90%, of which general profiles and bars and small and medium-sized civil building profiles accounted for more than 80% of the bar, large and medium-sized profiles and special special profiles and bars accounted for only about 15%. The pipe accounts for about 8% of the aluminum alloy extruded material, while the shaped pipe and special special pipe account for only about 20% of the pipe. It can be seen from the above that the largest production and sales of aluminum and aluminum alloy extrusion materials and the most widely used are small and medium-sized civil building profiles, general profiles and bars and pipes. And special profiles, bars and pipes only account for about 15%, the main characteristics of such products are: with special functions or performance; Dedicated to a particular purpose; Having a large or small specification size; With extremely high dimensional accuracy or surface requirements. Therefore, the variety is more and the batch is less, the need to increase special processes or add some special equipment and tools, the production is difficult and the technical content is high, the production cost is increased and the added value is increased.

With the progress of science and technology and the continuous improvement of people’s living standards, higher and higher requirements have been put forward for the output, quality and variety of aluminum and aluminum alloy extrusion products, especially in recent years, the emergence of product personalization has promoted the development of special profiles and pipes with personalized characteristics and specific uses.

Ultra-precision profiles are widely used in electronic instruments, communications, post and telecommunications equipment, precision machinery, precision instruments, weak current equipment, aerospace, nuclear submarines and ships, automotive industry and other fields of small, thin wall, section size of very precise parts. Usually the tolerance requirements are very strict, for example, the section outline size tolerance is less than ±0.10mm, the wall thickness tolerance is less than ±0.05mm. In addition, the flatness, twisting and other form and position tolerances of extruded products are also very strict. In addition, in the extrusion process of special small ultra-precision aluminum alloy profiles, the equipment, the mold, the process are very strict requirements. Due to the rapid development of modern industry, cutting-edge national defense and scientific research and other undertakings and the improvement of the degree of personalization, the number, variety and quality of small ultra-precision profiles are increasingly high, although in recent years, has developed and produced a lot of high-quality small ultra-precision aluminum alloy profiles, but still can not meet the needs of the market, In particular, there is still a big gap between the domestic technology and equipment for the production of small ultra-precision aluminum alloy profiles and the international advanced level, which cannot meet the domestic and foreign market demand and must be caught up.

4. Conclusion

Aluminum and aluminum alloy special precision extrusion (profiles and pipes) is a kind of complex shape, thin wall thickness, dimensional tolerance and shape and position accuracy requirements are very demanding, high technical content, difficult production of high, fine materials, is the national economy and national defense indispensable key materials, very wide range of uses, promising development prospects of the material. The production of this product has special requirements for billet, tooling and extrusion equipment and extrusion process, and a series of key technical problems must be solved in order to obtain excellent products in batches.

Edited by May Jiang from MAT Aluminum

Post time: Apr-07-2024