Aluminum is an excellent conductor of heat, and aluminum extrusions are contoured to maximize thermal surface area and create thermal pathways. A typical example is a computer CPU radiator, where aluminum is used to remove heat from the CPU.

Aluminum extrusions can be easily formed, cut, drilled, machined, stamped, bent and welded to suit specific purposes.

Basically any cross-sectional shape can be formed by aluminum extrusion, so the application range of aluminum extrusion is very wide. Because of the various advantages of aluminum extrusion, in some industries, aluminum extrusion is replacing other processes, such as machining and stamping, roll forming and merging multiple parts into one part to save welding and other processes.

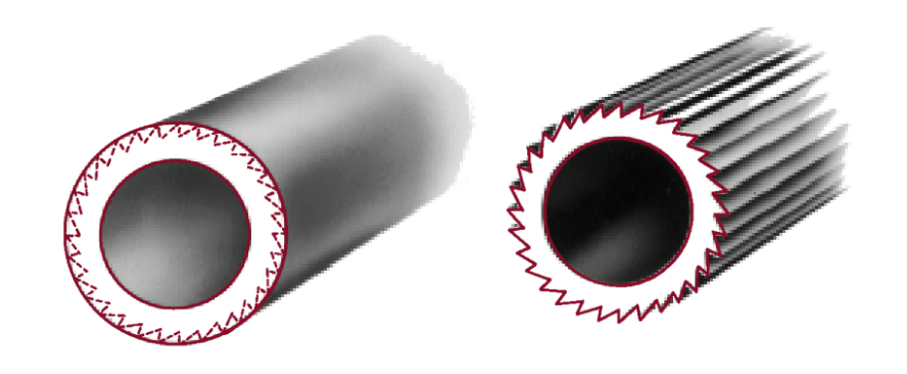

1. Aluminum extrusion instead of machining

Aluminum extrusion can be directly extruded into the required size and shape, reducing processing costs.

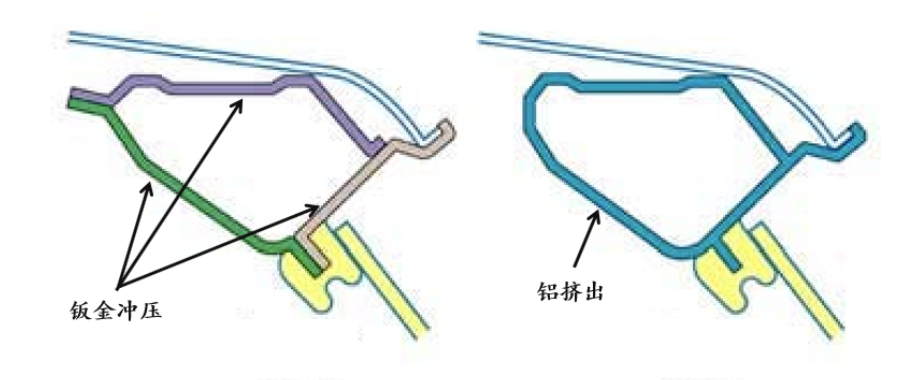

2. Aluminum extrusion replaces sheet metal stamping

In automobile bodies, aluminum extrusion replaces three sheet metal stamping parts and their corresponding welding and other processes.

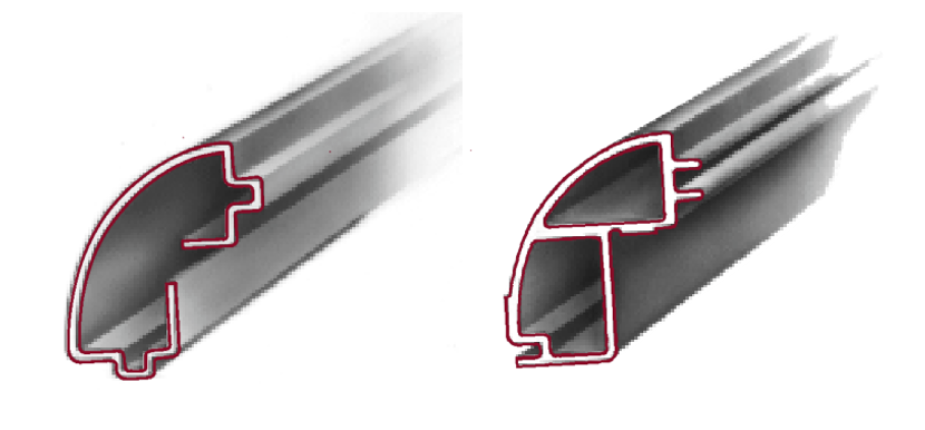

3. Aluminum extrusion instead of roll forming

Closed porous aluminum extrusions replace roll-formed parts, which improves strength while reducing costs and shortening development cycles.

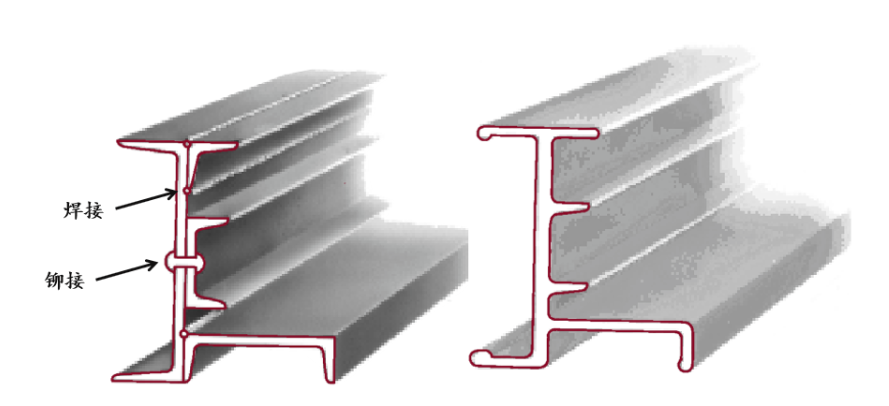

4. Aluminum extrusion replaces roll forming and corresponding assembly processes

The aluminum extrusion replaces four roll-formed parts and their corresponding welding and riveting processes.

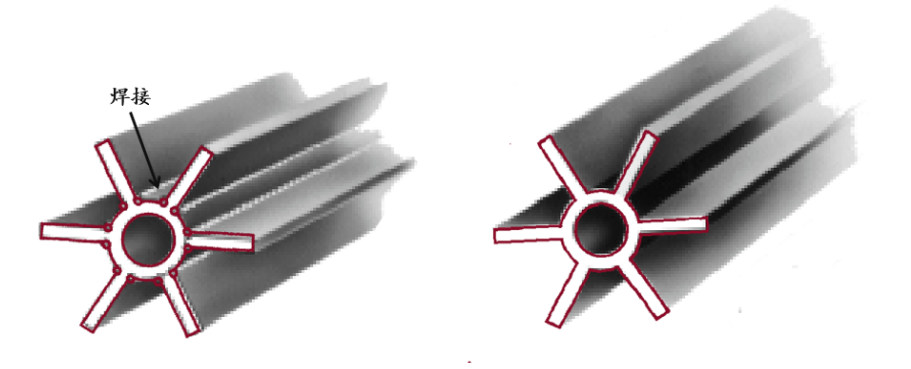

5. Aluminum extrusion merges multiple parts

Aluminum extrusions merge multiple parts to save the welding process while ensuring the strength of the parts.

Edited by May Jiang from MAT Aluminum

Post time: Jul-05-2024