Introduction

With the development of the automotive industry, the market for aluminum alloy impact beams is also growing rapidly, albeit still relatively small in overall size. According to the forecast by the Automotive Lightweight Technology Innovation Alliance for the Chinese aluminum alloy impact beam market, by 2025, the market demand is estimated to be around 140,000 tons, with a market size expected to reach 4.8 billion RMB. By 2030, the market demand is projected to be approximately 220,000 tons, with an estimated market size of 7.7 billion RMB, and a compound annual growth rate of about 13%. The development trend of lightweighting and the rapid growth of mid-to-high-end vehicle models are important driving factors for the development of aluminum alloy impact beams in China. The market prospects for automotive impact beam crash boxes are promising.

As costs decrease and technology advances, aluminum alloy front impact beams and crash boxes are gradually becoming more widespread. Currently, they are used in mid-to-high-end vehicle models such as Audi A3, Audi A4L, BMW 3 series, BMW X1, Mercedes-Benz C260, Honda CR-V, Toyota RAV4, Buick Regal, and Buick LaCrosse.

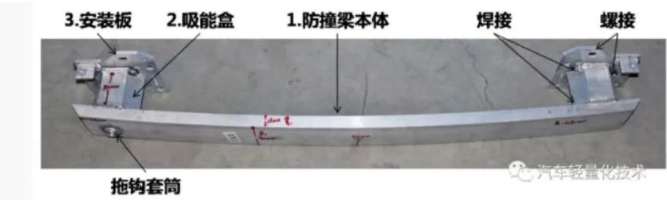

Aluminum alloy impact beams are mainly composed of impact crossbeams, crash boxes, mounting baseplates, and towing hook sleeves, as shown in Figure 1.

Figure 1: Aluminum Alloy Impact Beam Assembly

The crash box is a metal box located between the impact beam and two longitudinal beams of the vehicle, essentially serving as an energy-absorbing container. This energy refers to the force of impact. When a vehicle experiences a collision, the impact beam has a certain degree of energy-absorbing capability. However, if the energy exceeds the capacity of the impact beam, it will transfer the energy to the crash box. The crash box absorbs all of the impact force and deforms itself, ensuring that the longitudinal beams remain undamaged.

1 Product Requirements

1.1 Dimensions must adhere to the drawing’s tolerance requirements, as shown in Figure 2.

1.3 Mechanical Performance Requirements:

Tensile Strength: ≥215 MPa

Yield Strength: ≥205 MPa

Elongation A50: ≥10%

1.4 Crash Box Crushing Performance:

Along the vehicle’s X-axis, using a collision surface larger than the product’s cross-section, load at a speed of 100 mm/min until crushing, with a compression amount of 70%. The initial length of the profile is 300 mm. At the junction of the reinforcing rib and the outer wall, cracks should be less than 15 mm to be deemed acceptable. It should be ensured that the allowed cracking does not compromise the profile’s crushing energy-absorbing capacity, and there should be no significant cracks in other areas after crushing.

2 Development Approach

To simultaneously meet the requirements of mechanical performance and crushing performance, the development approach is as follows:

Use 6063B rod with a primary alloy composition of Si 0.38-0.41% and Mg 0.53-0.60%.

Perform air quenching and artificial aging to achieve the T6 condition.

Employ mist + air quenching and conduct over-aging treatment to achieve the T7 condition.

3 Pilot Production

3.1 Extrusion Conditions

Production is carried out on a 2000T extrusion press with an extrusion ratio of 36. The material used is homogenized aluminum rod 6063B. The heating temperatures of the aluminum rod are as follows: IV zone 450-III zone 470-II zone 490-1 zone 500. The main cylinder’s breakthrough pressure is around 210 bar, with the stable extrusion phase having an extrusion pressure close to 180 bar. The extrusion shaft speed is 2.5 mm/s, and the profile extrusion speed is 5.3 m/min. The temperature at the extrusion outlet is 500-540°C. The quenching is done using air cooling with the left fan power at 100%, middle fan power at 100%, and right fan power at 50%. The average cooling rate within the quenching zone reaches 300-350°C/min, and the temperature after exiting the quenching zone is 60-180°C. For mist + air quenching, the average cooling rate within the heating zone reaches 430-480°C/min, and the temperature after exiting the quenching zone is 50-70°C. The profile exhibits no significant bending.

3.2 Aging

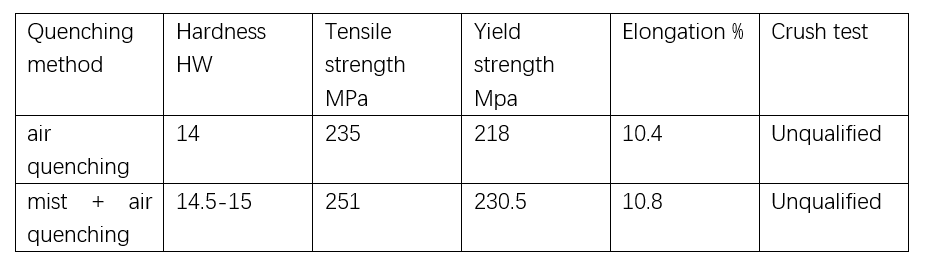

Following the T6 aging process at 185°C for 6 hours, the material’s hardness and mechanical properties are as follows:

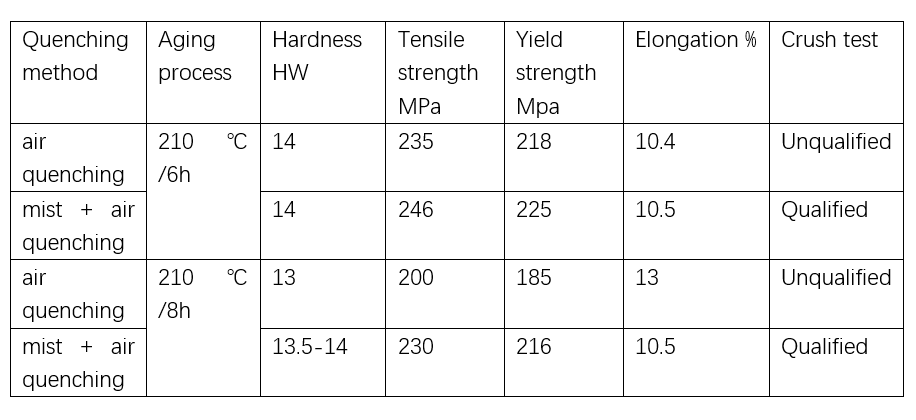

According to the T7 aging process at 210°C for 6 hours and 8 hours, the material’s hardness and mechanical properties are as follows:

Based on the test data, the mist + air quenching method, combined with the 210°C/6h aging process, meets the requirements for both mechanical performance and crushing testing. Considering cost-effectiveness, the mist + air quenching method and the 210°C/6h aging process were selected for production to meet the product’s requirements.

3.3 Crushing Test

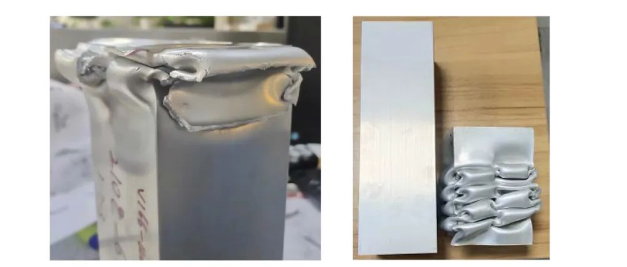

For the second and third rods, the head end is cut off by 1.5m, and the tail end is cut off by 1.2m. Two samples each are taken from the head, middle, and tail sections, with a length of 300mm. Crushing tests are conducted after aging at 185°C/6h and 210°C/6h and 8h (mechanical performance data as mentioned above) on a universal material testing machine. The tests are conducted at a loading speed of 100 mm/min with a compression amount of 70%. The results are as follows: for mist + air quenching with the 210°C/6h and 8h aging processes, the crushing tests meet the requirements, as shown in Figure 3-2, while the air-quenched samples exhibit cracking for all aging processes.

Based on the crushing test results, mist + air quenching with the 210°C/6h and 8h aging processes meet the customer’s requirements.

4 Conclusion

The optimization of quenching and aging processes is crucial for the successful development of the product and provides an ideal process solution for the crash box product.

Through extensive testing, it has been determined that the material state for the crash box product should be 6063-T7, the quenching method is mist + air cooling, and the aging process at 210°C/6h is the best choice for extruding aluminum rods with temperatures ranging from 480-500°C, extrusion shaft speed of 2.5 mm/s, extrusion die temperature of 480°C, and extrusion outlet temperature of 500-540°C.

Edited by May Jiang from MAT Aluminum

Post time: May-07-2024