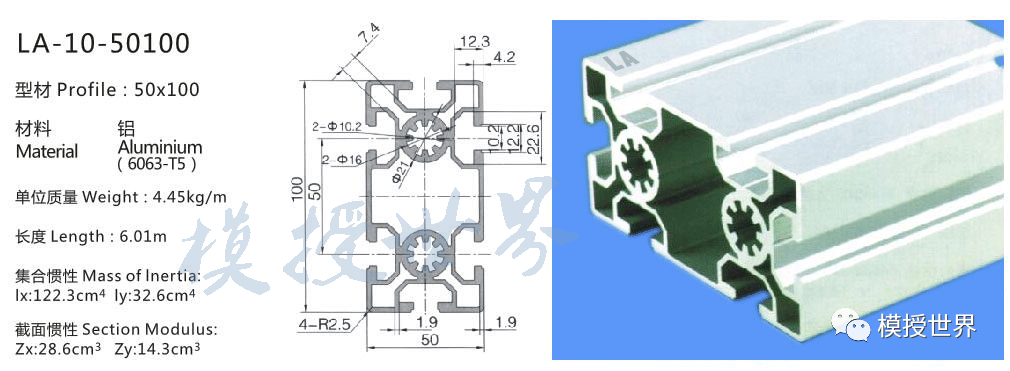

Aluminum profiles are mostly used as support materials, such as equipment frames, borders, beams, brackets, etc. The calculation of deformation is very important when selecting aluminum profiles. Aluminum profiles with different wall thicknesses and different cross-sections have different stress deformations.

How to calculate the load-bearing capacity of industrial aluminum profiles? We only need to know how to calculate the deformation of industrial aluminum profiles. Knowing the deformation of industrial aluminum profiles, we can also calculate the load-bearing capacity of the profiles.

So how to calculate the deformation based on the force on the profile?

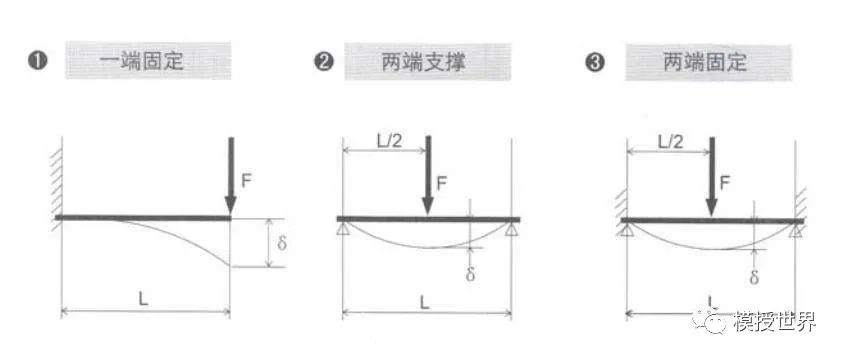

Let’s first take a look at the main ways to fix aluminum profiles. There are three types: fixed at one end, supported at both ends, and fixed at both ends. The calculation formulas for the force and deformation of these three fixing methods are different.

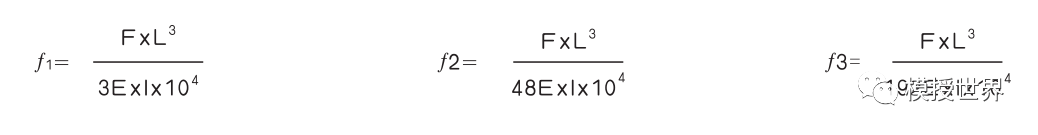

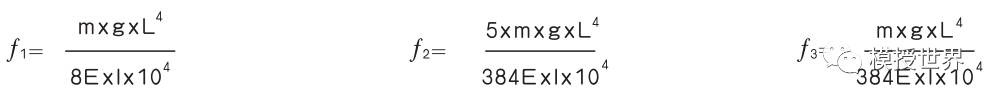

Let’s first look at the formula for calculating the deformation of aluminum profiles under static load:

The above are the formulas for calculating the static load deformation when one end is fixed, both ends are supported, and both ends are fixed. It can be seen from the formula that the deformation amount is the largest when one end is fixed, followed by support at both ends, and the smallest deformation is when both ends are fixed.

Let’s take a look at the formula for calculating deformation under no load:

Maximum allowable bending stress of aluminum profiles:

Maximum allowable bending stress of aluminum profiles:

Exceeding this stress may cause the aluminum profile to crack or even break.

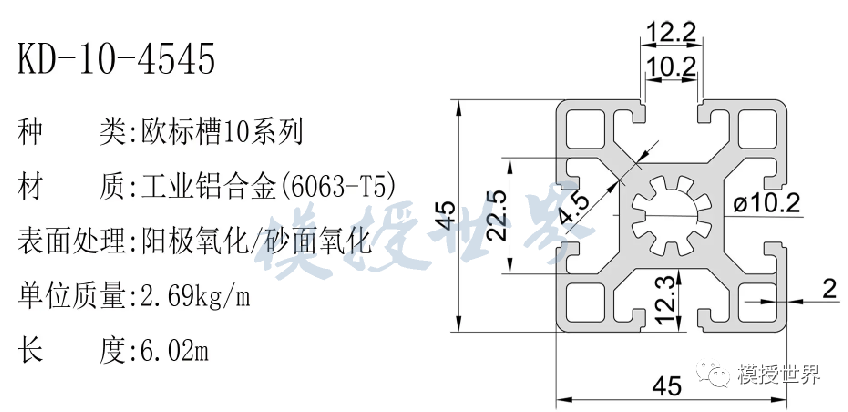

m: linear density of aluminum profile (kg/cm3)

F: Load (N)

L: Aluminum profile length

E: Elastic modulus (68600N/mm2)

I: collective inertia (cm4)

Z: Cross-sectional inertia (cm3)

g: 9.81N/kgf

f: Deformation amount (mm)

Give an example

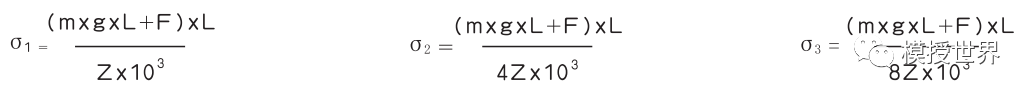

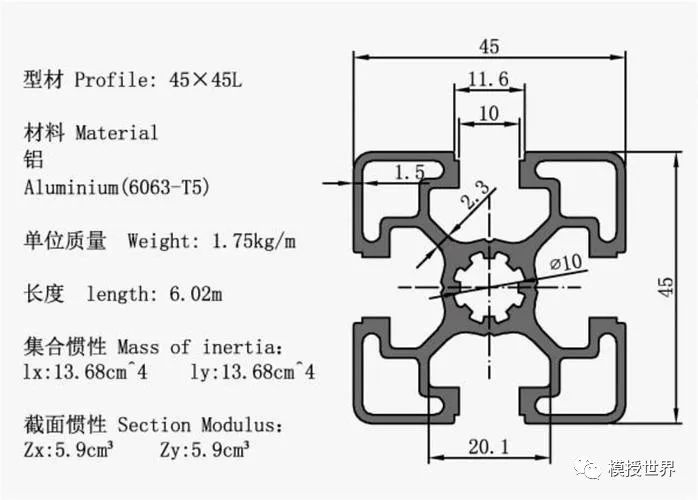

The above is the calculation formula for the force deformation of industrial aluminum profiles. Taking the 4545 aluminum profile as an example, we already know that the length of the aluminum profile is L=500mm, the load is F=800N (1kgf=9.81N), and both ends are fixedly supported, then the aluminum profile deformation amount = the force calculation formula of industrial aluminum profiles is: the calculation method is: deformation amount δ = (800×5003) / 192×70000×15.12×104≈0.05mm. This is the deformation amount of 4545 industrial aluminum profile.

When we know the deformation of industrial aluminum profiles, we put the length and deformation of the profiles into the formula to get the bearing capacity. Based on this method, we can give an example. The load-bearing calculation of 1 meter 1 meter 1 meter using 2020 industrial aluminum profiles roughly shows that the load-bearing capacity is 20KG. If the frame is paved, the load-bearing capacity can be increased to 40KG.

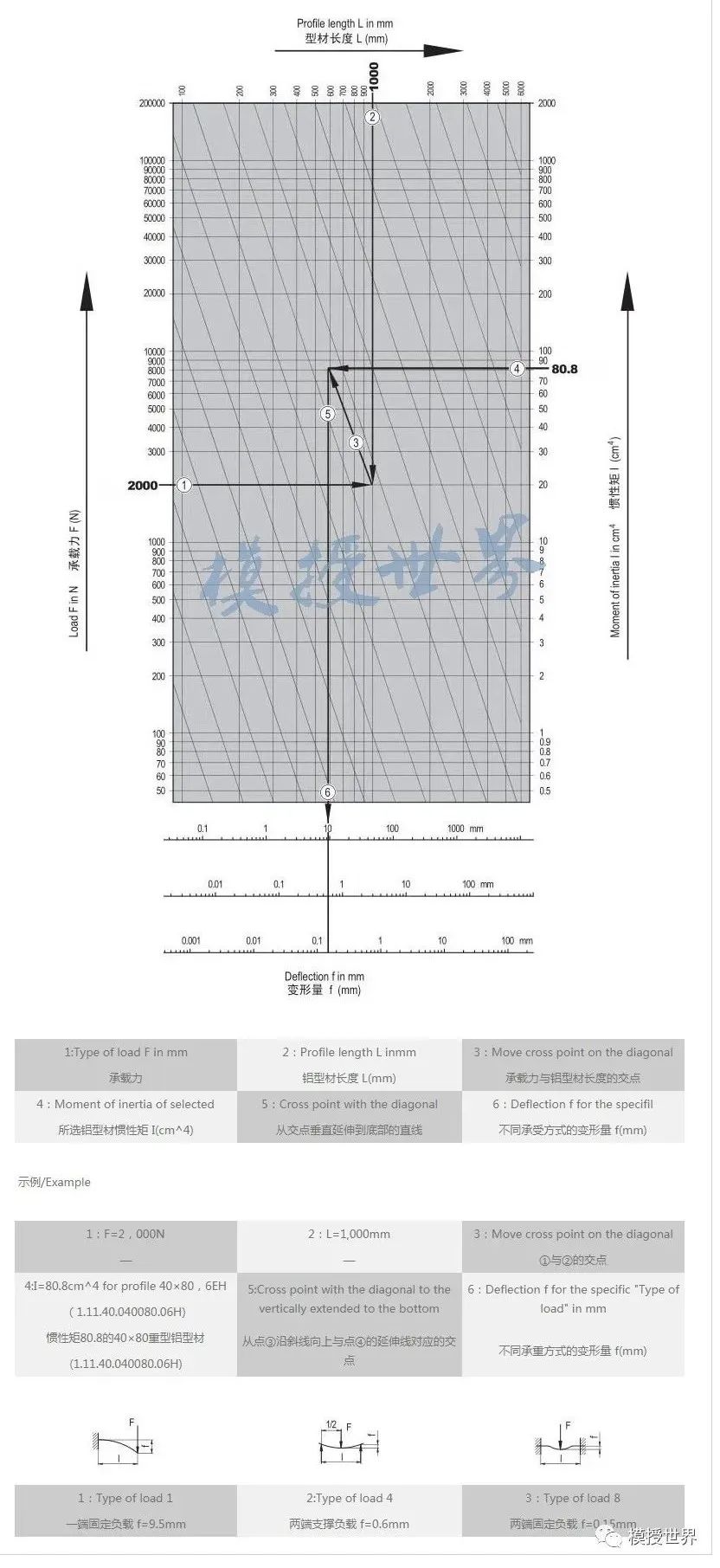

Aluminum profile deformation quick check table

The aluminum profile deformation quick check table is mainly used to describe the deformation amount achieved by aluminum profiles of different specifications under the influence of external forces under different fixation methods. This deformation amount can be used as a numerical reference for the physical properties of the aluminum profile frame; designers can use the following figure to quickly calculate the deformation of aluminum profiles of different specifications in different states;

Aluminum profile size tolerance range

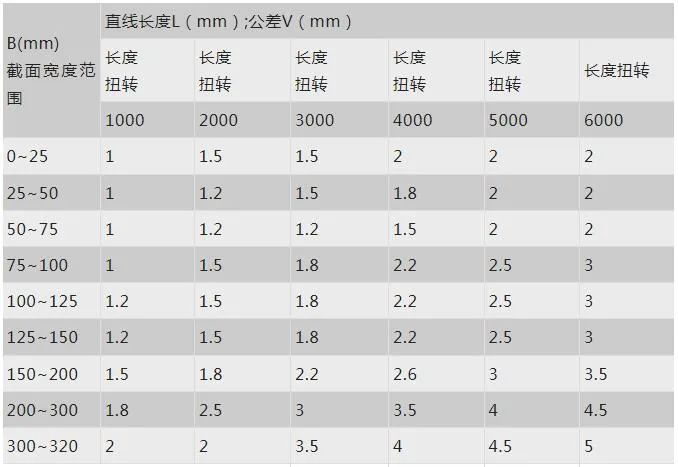

Aluminum profile torsion tolerance range

Aluminum profile transverse straight line tolerance

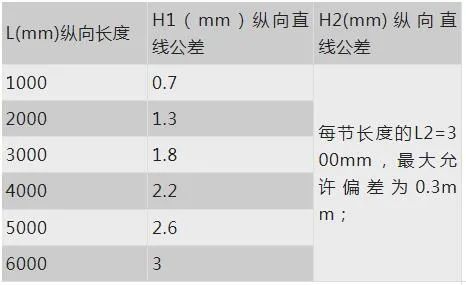

Aluminum profile longitudinal straight line tolerance

Aluminum profile angle tolerance

Above we have listed the standard dimensional tolerance range of aluminum profiles in detail and provided detailed data, which we can use as a basis to determine whether aluminum profiles are qualified products. For the detection method, please refer to the schematic diagram below.

Edited by May Jiang from MAT Aluminum

Post time: Jul-11-2024