1.Introduction

Aluminum alloys with medium strength exhibit favorable processing characteristics, quenching sensitivity, impact toughness, and corrosion resistance. They are extensively employed in various industries, such as electronics and marine, for manufacturing pipes, rods, profiles, and wires. Currently, there is an increasing demand for 6082 aluminum alloy bars. To meet market demands and user requirements, we conducted experiments on different extrusion heating processes and final heat treatment processes for 6082-T6 bars. Our goal was to identify a heat treatment regimen that satisfies the mechanical performance requirements for these bars.

2.Experimental Materials and Production Process Flow

2.1 Experimental Materials

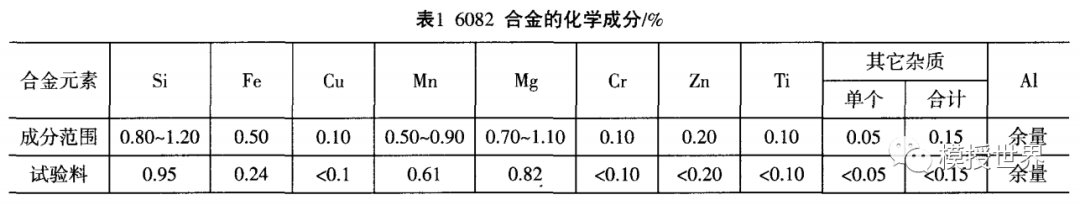

Casting ingots of size Ф162×500 were produced using a semi-continuous casting method and subjected to non-uniform treatment. The metallurgical quality of the ingots complied with company internal control technical standards. The chemical composition of the 6082 alloy is shown in Table 1.

2.2 Production Process Flow

The experimental 6082 bars had a specification of Ф14mm. The extrusion container had a diameter of Ф170mm with a 4-hole extrusion design and an extrusion coefficient of 18.5. The specific process flow included heating the ingot, extrusion, quenching, stretching straightening and sampling, roller straightening, final cutting, artificial aging, quality inspection, and delivery.

3.Experimental Objectives

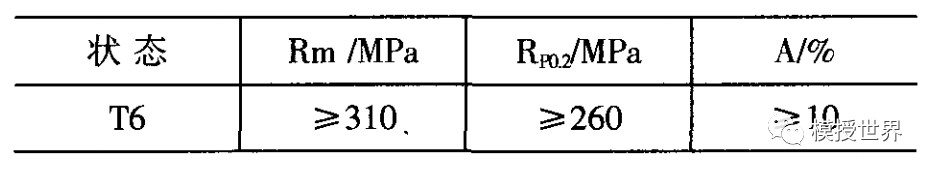

The aim of this study was to identify the extrusion heat treatment process parameters and final heat treatment parameters that influence the performance of 6082-T6 bars, ultimately achieving standard performance requirements. According to the standards, the longitudinal mechanical properties of the 6082 alloy should meet the specifications listed in Table 2.

4.Experimental Approach

4.1 Extrusion Heat Treatment Investigation

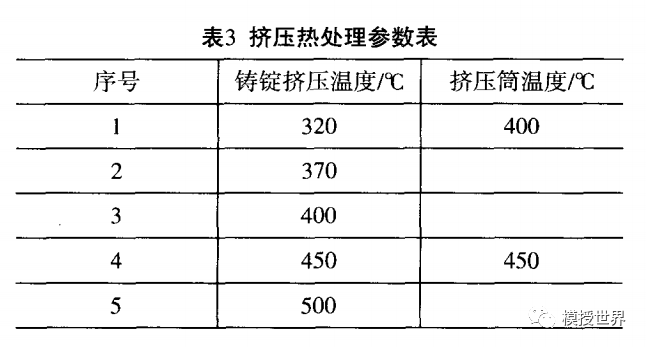

The extrusion heat treatment investigation primarily focused on the effects of casting ingot extrusion temperature and extrusion container temperature on mechanical properties. The specific parameter selections are detailed in Table 3.

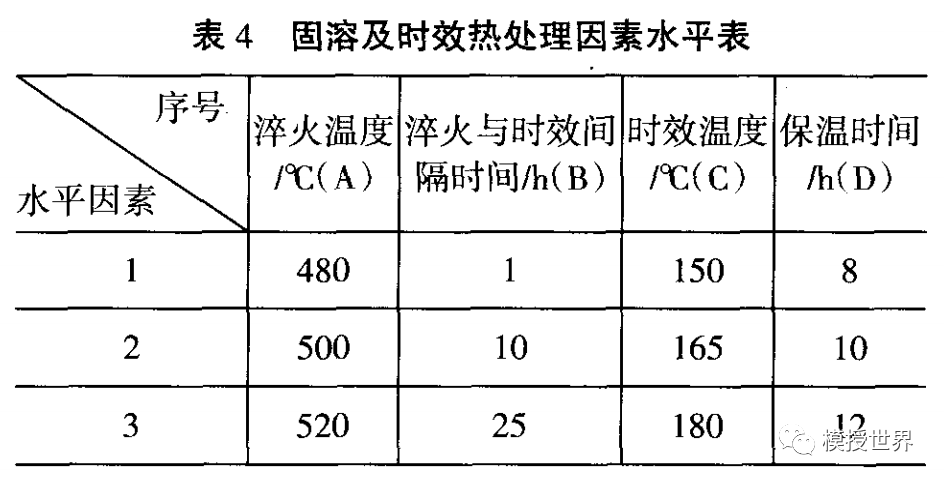

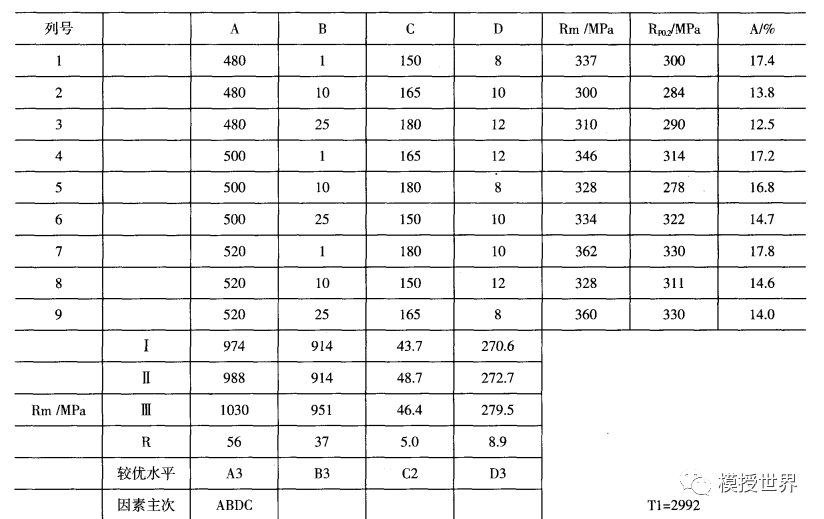

4.2 Solid Solution and Aging Heat Treatment Investigation

An orthogonal experimental design was employed for the solid solution and aging heat treatment process. The chosen factor levels are provided in Table 4, with the orthogonal design table denoted as IJ9(34).

5.Results and Analysis

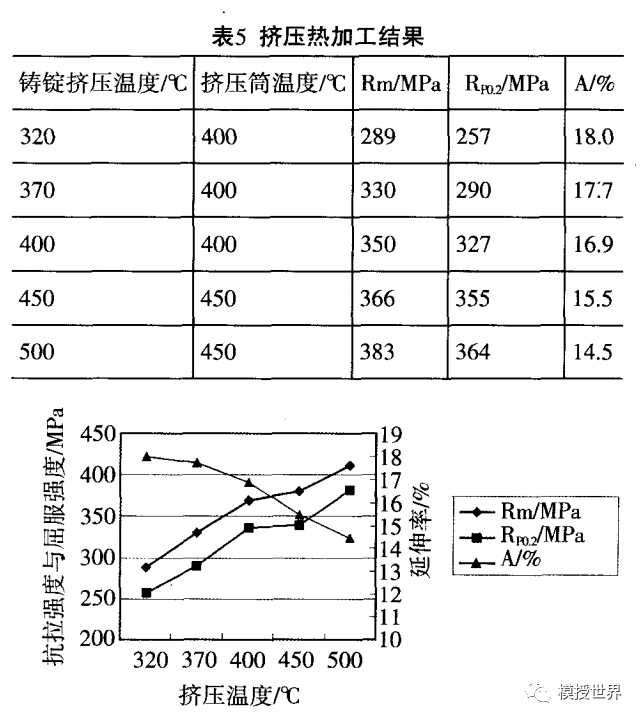

5.1 Extrusion Heat Treatment Experiment Results and Analysis

The results of the extrusion heat treatment experiments are presented in Table 5 and Figure 1. Nine samples were taken for each group, and their mechanical performance averages were determined. Based on metallographic analysis and chemical composition, a heat treatment regimen was established: quenching at 520°C for 40 minutes and aging at 165°C for 12 hours. From Table 5 and Figure 1, it can be observed that as the casting ingot extrusion temperature and extrusion container temperature increased, both tensile strength and yield strength gradually increased. The best results were obtained at extrusion temperatures of 450-500°C and an extrusion container temperature of 450°C, which met standard requirements. This was due to the effect of cold work hardening at lower extrusion temperatures, causing grain boundary fractures and increased solid solution decomposition between A1 and Mn during heating before quenching, leading to recrystallization. As the extrusion temperature increased, the ultimate strength Rm of the product significantly improved. When the extrusion container temperature approached or exceeded the ingot temperature, uneven deformation decreased, reducing the depth of coarse grain rings and increasing the yield strength Rm. Thus, the reasonable parameters for extrusion heat treatment are: ingot extrusion temperature of 450-500°C and extrusion container temperature of 430-450°C.

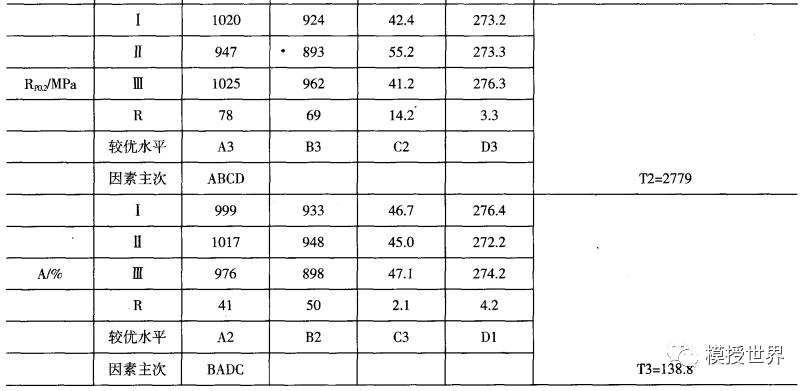

5.2 Solid Solution and Aging Orthogonal Experimental Results and Analysis

Table 6 reveals that the optimal levels are A3B1C2D3, with quenching at 520°C, artificial aging temperature between 165-170°C, and aging duration of 12 hours, resulting in high strength and plasticity of the bars. The quenching process forms supersaturated solid solution. At lower quenching temperatures, the concentration of supersaturated solid solution decreases, affecting strength. A quenching temperature of around 520°C significantly enhances the effect of quenching-induced solid solution strengthening. The interval between quenching and artificial aging, i.e., room temperature storage, greatly influences mechanical properties. This is particularly pronounced for rods that are not stretched after quenching. When the interval between quenching and aging exceeds 1 hour, strength, especially yield strength, decreases significantly.

5.3 Metallographic Microstructure Analysis

High-magnification and polarized analyses were conducted on 6082-T6 bars at solid solution temperatures of 520°C and 530°C. High-magnification photos revealed uniform compound precipitation with abundant precipitate phase particles evenly distributed. Polarized light analysis using Axiovert200 equipment showed distinct differences in grain structure photos. The central area displayed small and uniform grains, while the edges exhibited some recrystallization with elongated grains. This is due to the growth of crystal nuclei at high temperatures, forming coarse needle-like precipitates.

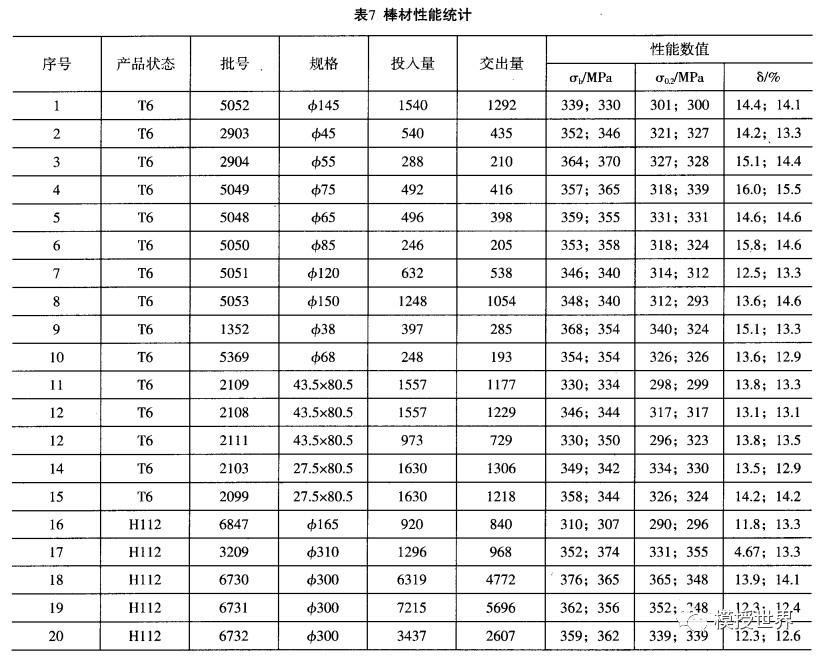

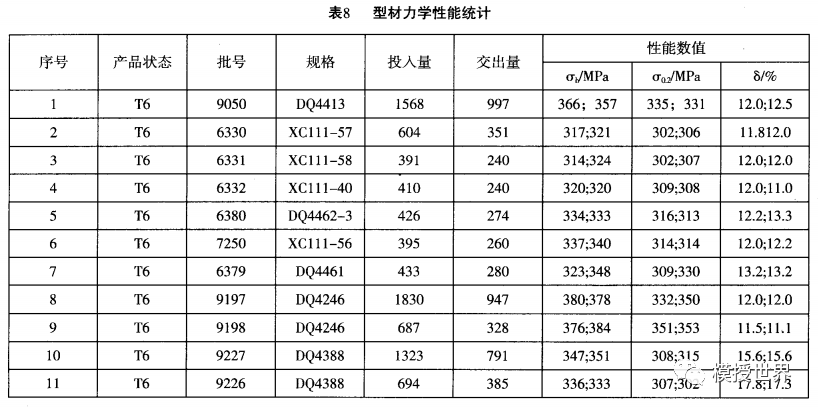

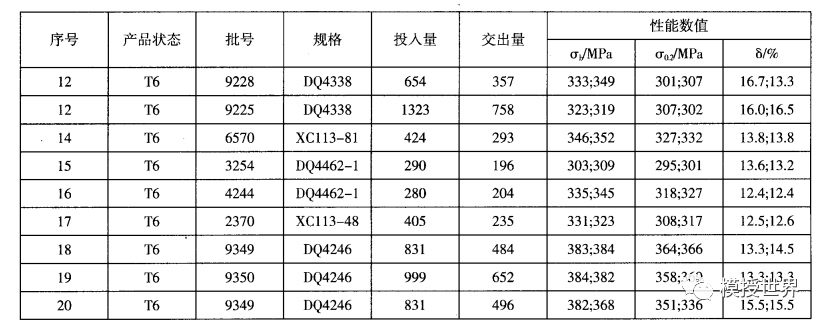

6.Production Practice Assessment

In actual production, mechanical performance statistics were conducted on 20 batches of bars and 20 batches of profiles. The results are shown in Tables 7 and 8. In actual production, our extrusion process was performed at temperatures resulting in T6 state samples, and the mechanical performance met the target values.

7.Conclusion

(1) Extrusion heat treatment parameters: Ingots extrusion temperature of 450-500°C; extrusion container temperature of 430-450°C.

(2) Final heat treatment parameters: Optimal solid solution temperature of 520-530°C; aging temperature at 165±5°C, aging duration of 12 hours; the interval between quenching and aging should not exceed 1 hour.

(3) Based on practical assessment, the viable heat treatment process includes: extrusion temperature of 450-530°C, extrusion container temperature of 400-450°C; solid solution temperature of 510-520°C; aging regimen of 155-170°C for 12 hours; no specific limit on the interval between quenching and aging. This can be incorporated into the process operation guidelines.

Edited by May Jiang from MAT Aluminum

Post time: Mar-15-2024