The vehicle body made of industrial aluminum profile materials has the advantages of light weight, corrosion resistance, good appearance flatness and recyclable materials, so it is favored by urban transportation companies and railway transportation departments around the world.

Industrial aluminum profile vehicle bodies have irreplaceable functions in the manufacture of high speed rail, so its development speed is very fast. At present, industrial aluminum profile vehicles with all-aluminum structure have been widely used in the manufacture of EMUs and urban rail transit vehicles, especially the steel structures of high-speed EMUs are all replaced by industrial aluminum profile vehicle bodies.

In the manufacturing process of industrial aluminum profile vehicle bodies, due to the extensive use of profile splicing in the structure, and the joints are long and regular, which is convenient for the realization of automatic operations, so various intelligent welding technologies are widely used in this industry.

Industrial aluminum profile vehicle bodie (Source: Finance Asia)

Automatic welding occupies a pivotal position in the welding of industrial aluminum profile vehicle bodies. It has been widely recognized by welding companies for its advantages of stable welding quality and high production efficiency. Now as the demand in the field of intelligent welding is greatly increased, it is believed that welding technology will be greatly developed in the near future.

Structural characteristics of industrial aluminum profile vehicle body for high-speed EMUs

The industrial aluminum profile vehicle body of the high-speed EMUs are mainly divided into the intermediate vehicle body of industrial aluminum profile and the head vehicle body of industrial aluminum profile. The intermediate vehicle body of industrial aluminum profile is mainly composed of four parts: the underframe, the side wall, the roof, and the end wall. The head vehicle body of industrial aluminum profile is mainly composed of five parts: the underframe, the side wall, the roof, the end wall and the front.

Application of automatic MIG welding technology in the manufacture of industrial aluminum profile vehicle bodies for high-speed EMUs

The welding of industrial aluminum profile of vehicle body in high-speed EMUs are usually divided into automatic welding of large parts, small parts and general assembly. Automatic welding of large parts generally refers to automatic welding of roof panels, flat roof panels, floors, roofs and side walls; Automatic welding of small parts generally refers to automatic welding of end walls, the fronts, partition walls, skirt plates and coupler seats. The automatic welding of the general assembly generally refers to the automatic welding of the joints between the side wall and the roof, and the side wall and the underframe. Investing in large-scale key welding equipment is a necessary condition for manufacturing industrial aluminum profile vehicle bodies.

In the initial stage of the production of high-speed EMU industrial aluminum profiles, single-wire IGM welding robot were used for automatic welding. With the expansion of EMU production capacity and the adjustment of process layout, single-wire IGM welding robot have been abandoned due to their low production efficiency. Up to now, all large parts of industrial aluminum profile vehicle bodies of high-speed EMU are welded by dual wire IGM welding robot.

The wide application of automatic MIG welding technology in the manufacture of high-speed EMU industrial aluminum profile vehicle bodies has greatly improved the level of welding technology and the manufacturing capacity of the production line, thus ensuring the product quality of industrial aluminum profile vehicle bodies of high-speed EMU, has made outstanding contributions to the field of high-speed rail manufacturing.

IGM welding robot

Application of Friction Stir Welding Technology in Manufacture of Industrial Aluminum Profile vehicle Body of High-speed EMUs

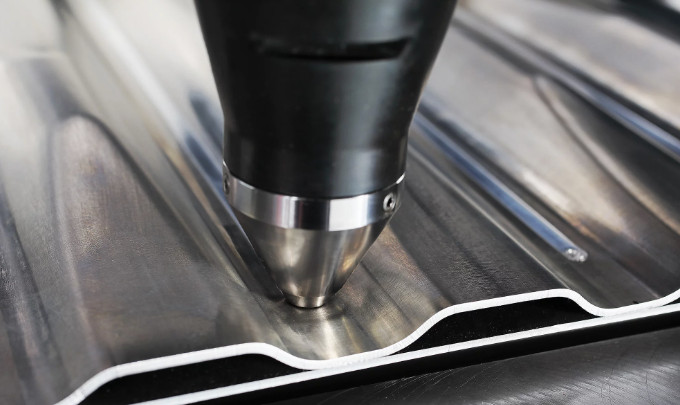

Friction Stir Welding(Source: grenzebach)

Friction stir welding (FSW) is a solid-phase joining technique. The welded joint has excellent mechanical properties and small welding deformation. It does not need to add shielding gas and welding wire, and there is no melting, dust, spatter and arc light during the welding process, which is a new environmentally friendly connection technology. In just a few years after the advent of FSW technology, great progress has been made in its welding mechanism, applicable materials, welding equipment and engineering applications.

Edited by May Jiang from MAT Aluminum

Feb. 15, 2023

Post time: Feb-18-2023