Aluminum alloy has low density, but relatively high strength, which is close to or exceeds that of high-quality steel. It has good plasticity and can be processed into various profiles. It has excellent electrical conductivity, thermal conductivity and corrosion resistance. It is widely used in industry, and its usage is second only to steel. Some aluminum alloys can be heat treated to obtain good mechanical properties, physical properties and corrosion resistance, and are a type of non-ferrous metal structural materials widely used in industry. It has been widely used in aviation, aerospace, automobile, machinery manufacturing, shipbuilding and chemical industry. Researchers continue to explore and develop aluminum alloys with new compositions and improved performance characteristics. Therefore, aluminum alloys are also constantly entering new industries.

All-aluminum household

Green aluminum alloy furniture has become a trend, and the aluminum alloy furniture produced by large aluminum processing enterprises represented by the Guangdong household market in China is derived from a series of processing of mineral resources, which can be reused, and there will be no excessive formaldehyde in general furniture. All aluminum furniture is not easy to deform, but also has the function of fire and moisture-proof. In addition, even if it is eliminated, aluminum alloy furniture will not waste resources on the social environment and destroy the ecological environment.

Aluminum alloy flyover

At present, the materials of China’s flyovers are mainly steel and other non-aluminum alloys, and the proportion of completed aluminum alloy flyovers is less than 2‰. With the rapid development of China’s economy and society, aluminum alloy flyovers have received more and more attention and recognition due to their advantages such as light weight, high specific strength, beautiful appearance, corrosion resistance, recyclability, and environmental protection. Calculated on the basis of a general medium-sized 30-meter-long flyover (including approach bridges), the amount of aluminum used is about 50 tons. Not only flyovers can be made of aluminum, but in foreign countries, the application of aluminum in highway bridges first appeared in 1933. With the recognition and acceptance of aluminum use by relevant domestic departments, if highway bridges can gradually increase the proportion of aluminum used, the amount of aluminum used will be much greater than that of flyovers.

New energy vehicles

Aluminum has become the material of choice for lightweighting new energy vehicles due to its low density, good corrosion resistance, excellent plasticity and easy recycling of aluminum alloys. As the technology of domestic manufacturers and component manufacturers continues to mature, the proportion and components of aluminum alloys used in domestic new energy vehicles are also increasing. As an important subdivision of the promotion of new energy vehicles in China, electric logistics vehicles are suitable for the promotion of electric logistics vehicles with all-aluminum bodies at different levels, and are expected to further open up the application space of aluminum alloys in new energy logistics vehicles.

Flood wall

The aluminum alloy flood wall has the characteristics of light weight and simple installation. Aluminum alloy can be used as the raw material of the flood wall. Based on the calculation of 40 kg per meter of aluminum alloy flood wall, the detachable aluminum alloy flood wall is about 1m high and is a three-piece combined structure. Each piece is 0.33m high, 3.6m long, and weighs about 30 kg. It is light and portable. Submarine-grade sealing strips are used between the three aluminum alloy plates, and the sealing performance is good. It is reported that the aluminum alloy plates are made of high-strength aluminum alloy, and the flood walls are connected with each other by cement piles or aluminum alloy columns. In the test stage, one square meter of aluminum alloy plate can withstand the impact of 500 kilograms of floods, and has a strong ability to prevent floods.

Aluminum-air battery

Aluminum-air batteries have the advantages of high energy density, low price, abundant resources, green and pollution-free, and long discharge life. The energy density of kilowatt-level aluminum-air batteries is more than 4 times that of current commercial lithium-ion power batteries, 1 kg Aluminum can allow electric vehicles to run 60 kilometers and double the battery life of electric vehicles. Aluminum-air batteries have attractive market prospects in the backup power supply of communication base stations and the application of range extenders for electric vehicles. In the process of use, it can realize zero emission, no pollution, and is easy to recycle. It can be used as a power battery, a signal battery, etc., and has broad application prospects.

Desalination

At present, the surface treatment technology of aluminum alloy tubes for seawater desalination is monopolized, and the application of “substituting aluminum for copper” in the heat transfer tubes of seawater desalination devices in China urgently needs to break through the anti-corrosion technology of the heat transfer tube coating, which is currently under research and development.

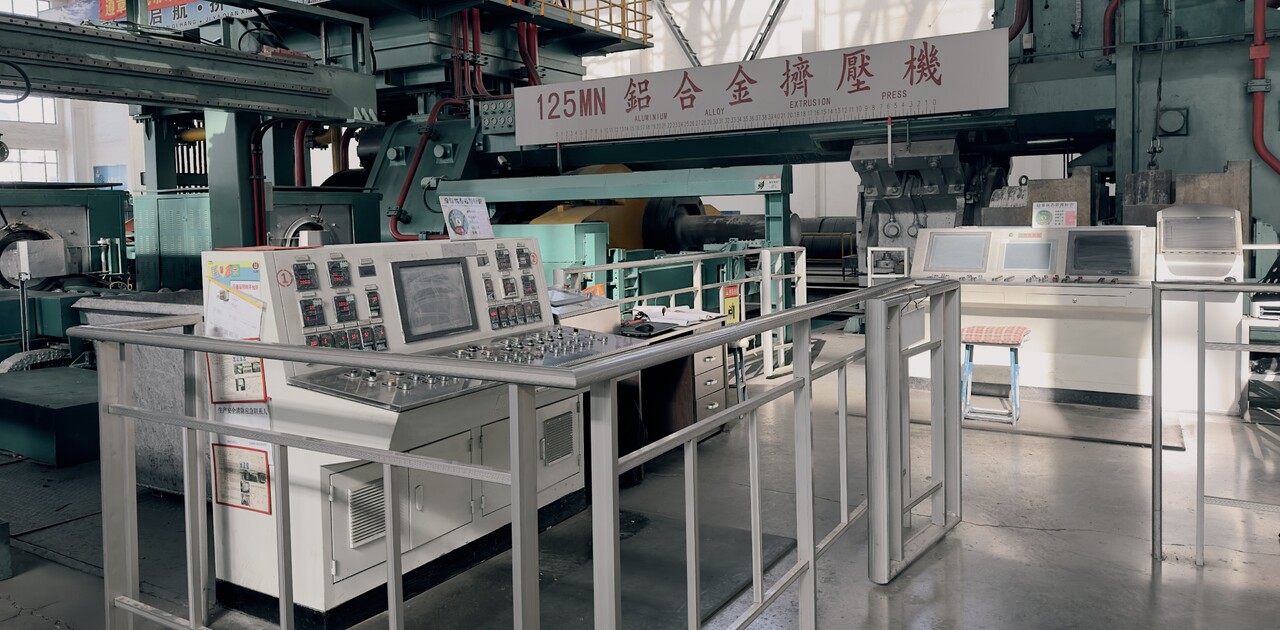

The scale and production technology of aluminum and aluminum processing industries in China and abroad have developed rapidly, reaching a fairly high level, and a large number of new aluminum alloy materials with various properties and functions, different varieties and uses have been developed. Alumina, electrolytic aluminum, aluminum alloy casting, casting, rolling, extrusion, pipe rolling, drawing, forging, powder making, fabrication and testing technologies are constantly being updated, and are aimed at energy saving, environmental protection and safety, simplification, continuous, high efficiency, High-quality, high-end direction of development, a large number of large-scale, precise, compact, high-efficiency, energy-saving and environmentally friendly, multi-functional, fully automatic aluminum and aluminum processing technology equipment have been developed.Large-scale, collectivized, large-scale, modernized and internationalized have become one of the important symbols of modern aluminum and aluminum processing enterprises.

Edited by May Jiang from MAT Aluminum

Post time: Jan-04-2024