News

NEWS CENTER

- Company News

- Industry Express

-

Intelligent Welding Technology for Industrial Aluminum Profile of EMUs

The vehicle body made of industrial aluminum profile materials has the advantages of light weight, corrosion resistance, good appearance flatness and recyclable materials, so it is favored by urban transportation companies and railway transportation departments around the world. Industrial alumin...

View More -

How to Optimize the Design of Aluminum Extrusion to Achieve Cost Reduction and High Efficiency

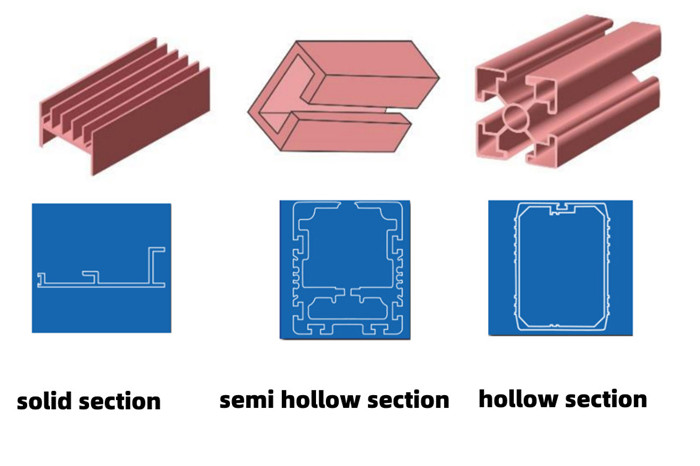

The section of aluminum extrusion is divided into three categories: Solid section: low product cost, low mold cost Semi hollow section: the mold is easy to wear and tear and break, with high product cost and mold cost Hollow section: high product cost and mold cost, the highest mold cost for poro...

View More -

Goldman Raises Aluminum Forecasts on Higher Chinese and European Demand

▪ The bank says the metal will average $3,125 a ton this year ▪ Higher demand could ‘trigger scarcity concerns,’ banks says Goldman Sachs Group Inc. raised its price forecasts for aluminum, saying higher demand in Europe and China could lead to supply shortages. The metal will probably aver...

View More

-

Main Production Equipment, Production Process and Parameters of Aluminum Alloy Strip

Aluminum strip refers to sheet or strip made of aluminum as the main raw material and mixed with other alloy elements. Aluminum sheet or strip is an important basic material for economic development and is widely used in aviation, aerospace, construction, printing, transportation, electronics, ch...

View More -

Why do lithium batteries use aluminum as shells?

The main reasons for lithium batteries to use aluminum shells can be analyzed in detail from the following aspects, namely lightweight, corrosion resistance, good conductivity, good processing performance, low cost, good heat dissipation performance, etc. 1. Lightweight • Low density: The ...

View More -

Aluminum Industry Chain Market Outlook and Strategy Analysis

In 2024, under the dual influence of the global economic pattern and domestic policy orientation, China’s aluminum industry has shown a complex and changeable operating situation. On the whole, the market size continues to expand, and aluminum production and consumption have maintained grow...

View More