Reuters seems to have excellent sources deep within Tesla. In a report dated September 14, 2023, it says no fewer than 5 people have told it the company is getting close to its goal of casting the underbody of its cars in one piece. Die casting is basically a fairly simple process. Create a mold, fill it with molten metal, let it cool, remove the mold, and voila! Instant car. It works well if you are making Tinkertoys or Matchbox cars, but its extremely difficult if you try to use it to make full size vehicles.

Conestoga wagons were built on top of frames made of timber. Early automobiles also used wooden frames. When Henry Ford created the first assembly line, the norm was to build vehicles on a ladder frame — two iron rails tied together with cross pieces. The first unibody production car was the Citroen Traction Avant in 1934, followed by the Chrysler Airflow the following year.

Unibody cars have no frame underneath them. Instead, the metal body is shaped and formed in such a way that it can support the weight of the drivetrain and protect the occupants in the event of a crash. Beginning in the 1950s, automakers, spurred by manufacturing innovations pioneered by Japanese companies like Honda and Toyota, switched to making unibody cars with front-wheel drive.

The entire powertrain, complete with engine, transmission, differential, driveshafts, struts, and brakes, was installed on a separate platform that was lifted into place from below on the assembly line, rather than dropping the engine and transmission in from above the way it was done for cars built on a frame. The reason for the change? Faster assembly times which led to lower unit costs of production.

For a long time, unibody technology was preferred for so-called economy cars while ladder frames were the choice for larger sedans and wagons. There were some hybrids mixed in — cars with frame rails in front bolted to a unibody passenger compartment. The Chevy Nova and MGB were examples of this trend, which did not last long.

Tesla Pivots To High Pressure Casting

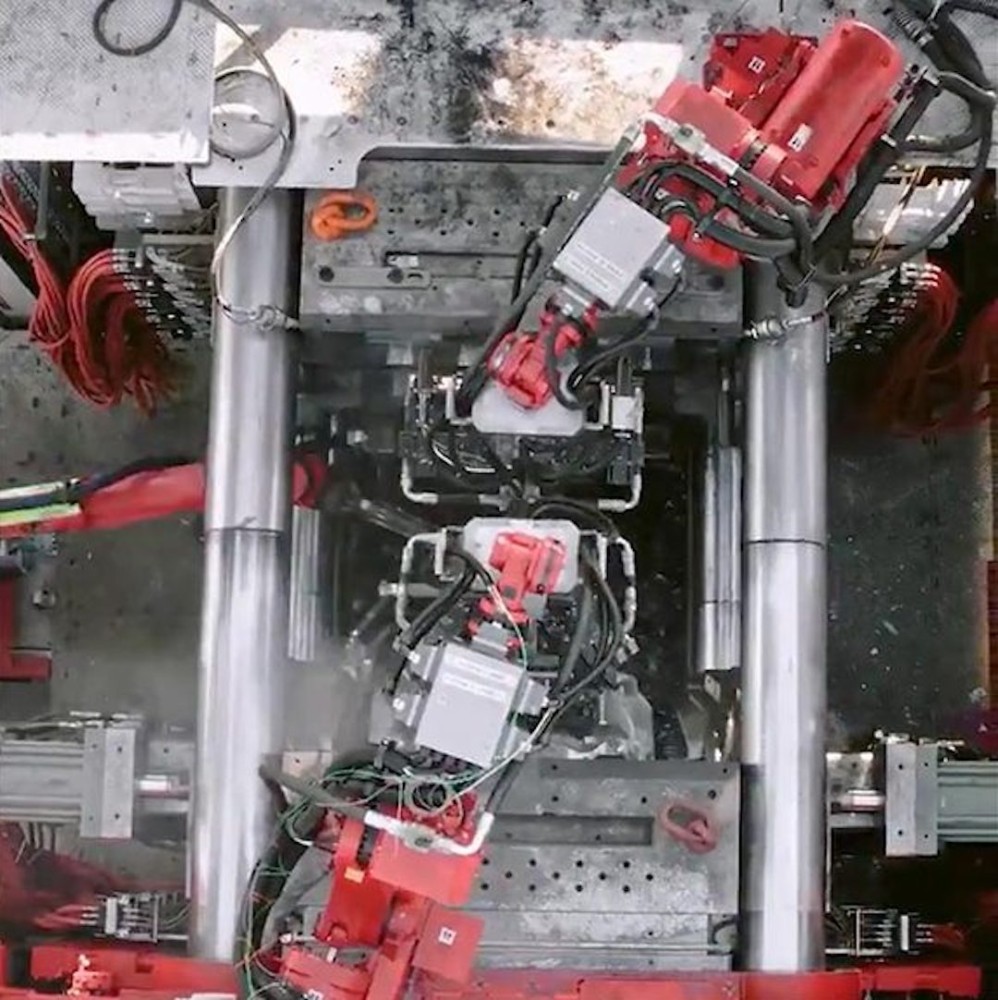

Tesla, which has made a habit of disrupting how automobiles are made, started experimenting with high pressure castings several years ago. First it focused on making the rear structure. When it got that right, it switched to making the front structure. Now, according to sources, Tesla is focusing on pressure casting the front, center, and rear sections all in one operation.

Why? Because traditional manufacturing techniques use up to 400 individual stampings that then have to be welded, bolted, screwed, or glued together to make a complete unibody structure. If Tesla can get this right, its cost of manufacturing could be slashed by up to 50 percent. That, in turn, will put tremendous pressure on every other manufacturer to respond or find themselves unable to compete.

It goes without saying that those manufacturers are feeling battered from all sides as uppity unionized workers are banging on the gates and demanding a bigger slice of whatever profits are still being earned.

Terry Woychowsk, who worked at General Motors for 3 decades, knows a thing or two about manufacturing automobiles. He is now the president of U.S. engineering company Caresoft Global. He tells Reuters that if Tesla manages to gigacast most of the underbody of an EV, it would further disrupt the way cars are designed and manufactured. “It is an enabler on steroids. It has a huge implication for the industry, but it’s a very challenging task. Castings are very hard to do, especially the bigger and the more complicated.”

Two of the sources said Tesla’s new design and manufacturing techniques mean the company could develop a car from the ground up in 18 to 24 months, while most rivals can currently take anywhere from three to four years. A single large frame — combining the front and rear sections with the middle underbody where the battery is housed — could be used to manufacture a new, smaller electric car that retails for around $25,000. Tesla was expected to decide whether to die cast a one-piece platform as soon as this month, three of the sources said.

Significant Challenges Ahead

One of the biggest challenges for Tesla in using high pressure castings is designing subframes that are hollow but have the internal ribs needed to make them able to dissipate the forces that occur during crashes. The sources claim innovations by design and casting specialists in Britain, Germany, Japan, and the United States make use of 3D printing and industrial sand.

Making the molds needed for high pressure casting of large components can be quite expensive and comes with considerable risks. Once a large metal test mold has been made, machining tweaks during the design process could cost $100,000 a go, or redoing the mold altogether might come to $1.5 million, according to one casting specialist. Another said the whole design process for a large metal mold would typically cost about $4 million.

Many automakers have deemed the cost and the risks to be too high, especially since a design might need half a dozen or more tweaks to achieve a perfect die from the perspective of noise and vibration, fit and finish, ergonomics and crashworthiness. But risk is something that seldom bothers Elon Musk, who was the first to make rockets fly backwards.

Industrial Sand & 3D Printing

Tesla reportedly has turned to firms that make test molds out of industrial sand with 3D printers. Using a digital design file, printers known as binder jets deposit a liquid binding agent onto a thin layer of sand and gradually build a mold, layer by layer, that can die cast molten alloys. According to one source, the cost of the design validation process with sand casting costs about 3% of doing the same thing with a metal prototype.

That means Tesla can tweak prototypes as many times as needed, reprinting a new one in a matter of hours using machines from companies such as Desktop Metal and its ExOne unit. The design validation cycle using sand casting only takes to two to three months, two of the sources said, compared with anywhere from six months to a year for a mold made from metal.

Despite that greater flexibility, however, there was still one more major hurdle to overcome before large scale castings could be made successfully. The aluminium alloys used to produce the castings behave differently in molds made of sand than they do in molds made of metal. Early prototypes often failed to meet Tesla’s specifications.

The casting specialists overcame that by formulating special alloys, fine tuning the molten alloy cooling process, and coming up with a post-production heat treatment, three of the sources said. Once Tesla is satisfied with the prototype sand mold, it can then invest in a final metal mold for mass production.

The sources said Tesla’s upcoming small car/robotaxi has given it a perfect opportunity to cast an EV platform in one piece, mainly because its underbody is simpler. Small cars don’t have a big “overhang” at the front and the back. “It’s like a boat in a way, a battery tray with small wings attached to both ends. That would make sense to do in one piece,” one person said.

The sources claimed that Tesla still has to decide what kind of press to use if it decides to cast the underbody in one piece. To manufacture large body parts quickly will require bigger casting machines with clamping power of 16,000 tons or more. Such machines will be expensive and may require larger factory buildings.

Presses with high clamping power cannot accommodate the 3D-printed sand cores needed to make hollow subframes. To solve that problem, Tesla is using a different type of press into which molten alloy can be injected slowly — a method that tends to produce higher quality castings and can accommodate the sand cores.

The problem is: that process takes longer. “Tesla could still choose high pressure for productivity, or they could choose slow alloy injection for quality and versatility,” one of the people said. “It’s still a coin toss at this point.”

The Takeaway

Whatever decision Tesla makes, it will have implications that will ripple throughout the auto industry worldwide. Tesla, despite significant price cuts, is still making electric cars at a profit — something legacy automakers are finding extremely difficult to do.

If Tesla can trim its costs of manufacturing significantly by using high pressure castings, those companies will be under even greater pressure economically. It is not hard to imagine what happened to Kodak and Nokia happening to them. Where that would leave the world economy and all the workers who currently make conventional cars is anyone’s guess.

Source: https://cleantechnica.com/2023/09/17/tesla-may-have-perfected-one-piece-casting-technology/

Author: Steve Hanley

Edited by May Jiang from MAT Aluminum

Post time: Jun-05-2024