Industry News

-

Overview of Aluminum Ingot Casting Process

I. Introduction The quality of primary aluminum produced in aluminum electrolytic cells varies significantly, and it contains various metal impurities, gases, and non-metal solid inclusions. The task of aluminum ingot casting is to improve the utilization of low-grade aluminum liquid and remove ...

View More -

What is the Relationship between Heat Treatment Process, Operation, and Deformation?

During the heat treatment of aluminum and aluminum alloys, various issues are commonly encountered, such as: -Improper part placement: This can lead to part deformation, often due to insufficient heat removal by the quenching medium at a fast enough rate to achieve the desired mechanical properti...

View More -

Introduction of 1-9 Series Aluminum Alloy

Series 1 Alloys like 1060, 1070, 1100, etc. Characteristics: Contains over 99.00% aluminum, good electrical conductivity, excellent corrosion resistance, good weldability, low strength, and cannot be strengthened by heat treatment. Due to the absence of other alloying elements, the production pr...

View More -

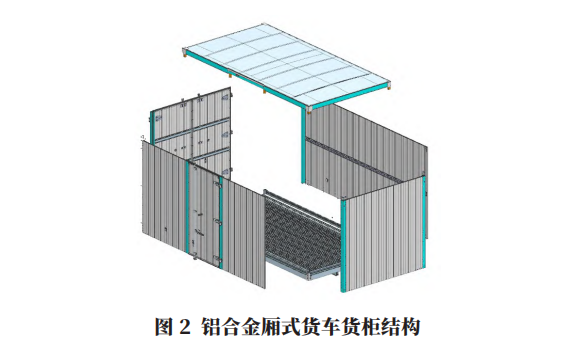

Application Research of Aluminum Alloy on Box Type Trucks

1.Introduction Automotive lightweighting began in developed countries and was initially led by traditional automotive giants. With continuous development, it has gained significant momentum. From the time when Indians first used aluminum alloy to produce automotive crankshafts to Audi’s fir...

View More -

Inventory of New Areas for the Development of High-end Aluminum Alloys

Aluminum alloy has low density, but relatively high strength, which is close to or exceeds that of high-quality steel. It has good plasticity and can be processed into various profiles. It has excellent electrical conductivity, thermal conductivity and corrosion resistance. It is widely used in ...

View More -

Five Characteristics of Industrial Aluminum Profiles

Industrial aluminum profiles, as one of the main varieties of aluminum profiles, are increasingly being used in various fields such as transportation, machinery, light industry, electronics, petroleum, aviation, aerospace, and chemical industry, thanks to their advantages of formable by one extru...

View More -

Common Spotted Defects in Anodized Aluminum Profiles

Anodizing is a process used to create an aluminum oxide film on the surface of aluminum or aluminum alloy products. It involves placing the aluminum or aluminum alloy product as the anode in an electrolyte solution and applying an electric current to form the aluminum oxide film. Anodizing impro...

View More -

Application Status and Development Trend of Aluminum Alloy in European Automobiles

The European automobile industry is famous for its advanced and highly innovative. With the promotion of energy saving and emission reduction policies, in order to reduce fuel consumption and carbon dioxide emissions, improved and innovatively designed aluminum alloys are widely used in automobil...

View More -

Application of High-End Aluminum Alloy Materials in Launch Vehicles

Aluminum alloy for rocket fuel tank Structural materials are closely related to a series of issues such as rocket body structure design, manufacturing and processing technology, material preparation technology, and economy, and are the key to determining the rocket’s take-off quality and pa...

View More -

Influence of Impurity Elements in Aluminum Alloy

Vanadium forms VAl11 refractory compound in aluminum alloy, which plays a role in refining grains in the melting and casting process, but the effect is smaller than that of titanium and zirconium. Vanadium also has the effect of refining the recrystallization structure and increasing the recrysta...

View More -

Determination of Holding Time and Transfer Time for Quenching Heat of Aluminum Profiles

The holding time of aluminum extruded profiles is mainly determined by the solid solution rate of the strengthened phase. The solid solution rate of the strengthened phase is related to the quenching heat temperature, the nature of the alloy, the state, the section size of the aluminum profile, t...

View More -

Aluminum Anodizing Production Process Specifications

Process Flow 1.Anodizing of silver-based materials and silver-based electrophoretic materials: Loading – Water rinsing – Low-temperature polishing – Water rinsing – Water rinsing – Clamping – Anodizing – Water rinsing – Water rinsing – Water r...

View More