News

NEWS CENTER

- Company News

- Industry Express

-

Intelligent Welding Technology for Industrial Aluminum Profile of EMUs

The vehicle body made of industrial aluminum profile materials has the advantages of light weight, corrosion resistance, good appearance flatness and recyclable materials, so it is favored by urban transportation companies and railway transportation departments around the world. Industrial alumin...

View More -

How to Optimize the Design of Aluminum Extrusion to Achieve Cost Reduction and High Efficiency

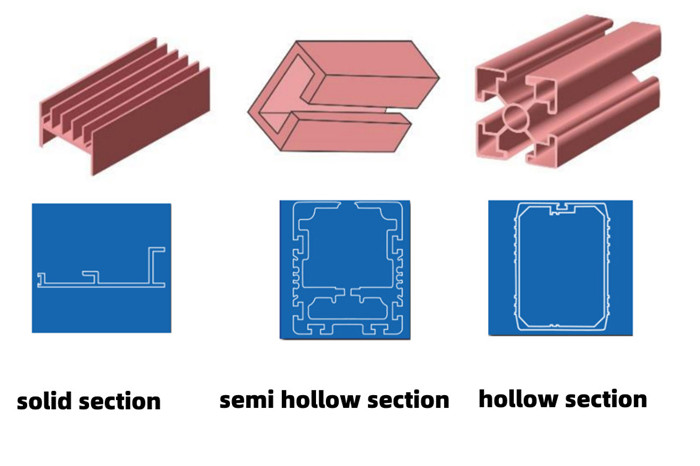

The section of aluminum extrusion is divided into three categories: Solid section: low product cost, low mold cost Semi hollow section: the mold is easy to wear and tear and break, with high product cost and mold cost Hollow section: high product cost and mold cost, the highest mold cost for poro...

View More -

Goldman Raises Aluminum Forecasts on Higher Chinese and European Demand

▪ The bank says the metal will average $3,125 a ton this year ▪ Higher demand could ‘trigger scarcity concerns,’ banks says Goldman Sachs Group Inc. raised its price forecasts for aluminum, saying higher demand in Europe and China could lead to supply shortages. The metal will probably aver...

View More

-

Aluminum Alloy Weight Calculation Formula Table

1. Verification of the physical principle of the core formula Law of Conservation of Mass All formulas are based on the physical nature of m=ρ×V (mass = density × volume) Density value Theoretical density of pure aluminum: 2,698 kg/m³ (20℃) The approximate value of 2,700 kg/m³ is reasonable for i...

View More -

The structure of 6082 alloy before and after homogenization

1. Alloy composition 2. Homogenization Process 390℃ x insulation for 1.0h + 575℃ x insulation for 8h, strong wind cooling to 200℃ and then water cooling. 3. Metallographic Structure (a) 50× (b) 100× Figure 1 Metallographic structure of the core of 6082 alloy ingot, etched by Keller rea...

View More -

Summary of knowledge on mold modification and welding

1. Different leather texture and color, welding spots Cause 1 : The material of the welding area is different from the original material. Corresponding measures: Use welding wire that is consistent with the base material, preferably special welding wire used in steel mills; secondly, saw the mate...

View More